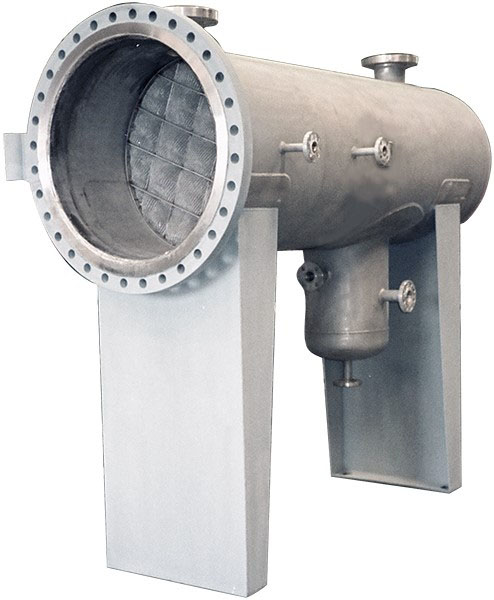

The Winston/Royal Guard Type 62-MM

Liquid-Liquid Coalescers employ a knitted wire mesh media pack and gravitational settling for the separation of two immiscible liquids

The Type 62HW-MM-1S and Type 62HO-MM-1S are single-stage liquid-liquid coalescers designed for the separation of two immiscible liquids such as small amounts of an aqueous solution from a hydrocarbon. Liquid-liquid coalescers have applications in refining, oil & gas, and related industries.

Applications include separation of:

- Water from kerosene, gasoline, and diesel

- Caustic from kerosene, gasoline, and diesel

- Oil from anhydrous ammonia

- Oil from water

- Amine from NGL

- Other immiscible liquids with dissimilar densities

For each application the coalescer is designed for maximum dispersed phase liquid removal with minimal carryover. Variables which affect separation include velocity, viscosity, specific gravity, surfactants, and interfacial tension.

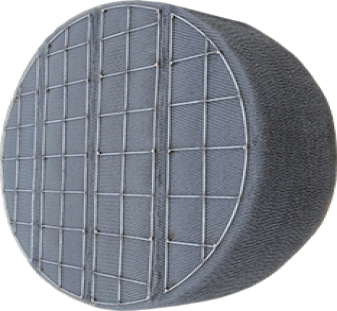

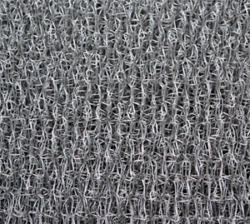

Coalescer Operation: The liquid-liquid coalescer utilizes a knitted wire mesh media pack for optimal separation of the two liquids. As the liquid emulsion flows through the media pack, dispersed phase droplets attach to the media pack’s filaments. As the flow continues, additional droplets attach to the filaments and merge, or coalesce, with other droplets. This coalescing process continues until the droplets have grown large enough to release from the media pack and flow into the vessel interior. Here, gravitational forces cause the enlarged droplets to fall to the bottom of the vessel and are collected in the vessel’s boot, or collection chamber.

The boot will be located on the either the bottom or the top of the vessel depending on whether the discontinuous phase liquid is heavier than, or lighter than the continuous phase. If the discontinuous phase is heavier, the boot will be located on the bottom of the vessel; if lighter, the boot will be on the top of the vessel.

The coalescer can be provided with various styles of media packs including several wire filament densities. The filaments can also be inter-wound with fibers such as polypropylene, polyester, nylon, fiberglass, and Teflon® depending on chemical compatibility and the application. Wire filaments are available in various metals to include 300 series stainless steels, Monel 400, Nickel 200, Hastelloy C276, Inconel 600 and others. The media packs are also available in Teflon®, Kynar®, and polypropylene.

If the liquid emulsion contains solids, a filtration unit such as a Winston/Royal Guard Type 61 Liquid Filter should be installed upstream of the liquid-liquid coalescer separator to prevent fouling of the media pack and ensure optimal performance of the coalescer.