For Winston/Royal Guard Type 140 Coalescers

Available with either a 0.3 or 1 micron rating, the WCL536R Series gas-liquid coalescing cartridges remove liquid and solid particulates from gas or air. With a flow path from inside to outside, and excellent coalescing properties, these cartridges are for use in the Winston/Royal Guard Type 140 Gas-Liquid Coalescer for efficient removal of aerosol particles including water, glycol, and lube oil from natural gas. Extremely fine solid particulate matter will also be captured.

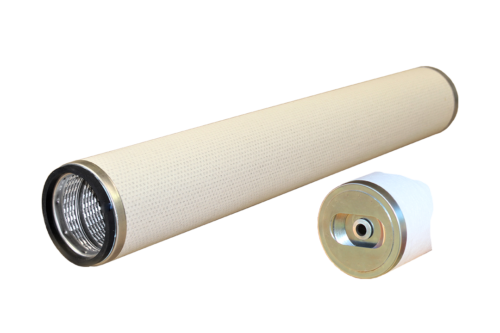

The photo above shows the optional ET Top Cap.

The cartridge employs glass fiber depth type media in combination with polypropylene coalescing media for the utmost in solid contaminant removal and liquid coalescing capacity. To provide the best structural integrity, the steel core is mechanically bonded to the end caps. Each cartridge has a closed end with a center hole for mounting, and an open end complete with a Buna N gasket for sealing (other gasket materials are available). The standard material for both the core and caps is tinned steel with stainless steel as an option. To complete the assembly, a polyester outer drainage layer surrounds the media to assist in rapid drainage of the coalesced liquids.

Optional “ET” Top Cap:

Optional “ET” Top Cap for easy cartridge removal with the extractor tool from the top area of the open coalescer vessel. The dual use top cap allows for cartridge installation with lock risers, which secure the cartridges in place and allow for loosening at the top of the vessel.

Benefits:

- Maximum solids-holding capacity and coalescing of liquids.

- Robust metal support core can withstand differential pressure over 50 PSI.

- Low pressure drop.

- Depth type cartridge offers efficiency at an economical cost.

Operation Specifications for these Coalescing Cartridges:

- Flow Direction is inside to outside.

- Available in a 0.3 or 1 micron rating at 99.9% efficiency.

- Recommended differential pressure for element change-out is 15 P.S.I.

- Maximum operating temperature is 180⁰ F.

- Minimum operating temperature is 35⁰ F.

Standard Dimensions:

- 36” Long -- 5 ½” O.D.

Standard Part Numbers and Micron Rating:

- WCL536R (0.3) for 0.3 micron and tinned steel core and end caps.

- WCL536R (1) for 1 micron and tinned steel core and end caps.

- Add "-304" or "-316" to part number for stainless steel core and end caps.

- Add “-ET” to part number for the optional ET Top Cap.