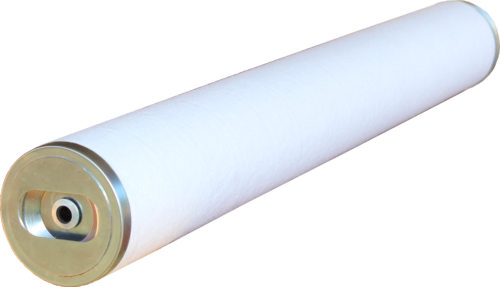

Coalescing Cartridges with "ET" Top cap for easy removal from Gas-Liquid Coalescer

For the Type 140 Gas-Liquid Coalescer, the W--L536Rb-ET series gas-liquid coalescing cartridges with the “ET” top cap are designed with personnel safety in mind allowing easy removal and replacement from the top area of the open coalescer vessel. The dual purpose top cap is ideal for securing the cartridge in place and easy removal with the extractor tool. These cartridges are provided in either a pleated media or a depth media and offer excellent coalescing properties with maximum removal of liquid and solid particles 0.3 micron and larger from gas or air.

Contaminants removed include liquid hydrocarbons, water, amine, glycol, and extremely fine solid particulate matter. Applications include recovery of compressor lube oil, glycol and amine mist carryover, fine solid particulate matter and contaminant protection for equipment, catalyst beds, and other critical applications in gas production, transportation, and processing industries.

For maximum efficiency these cartridges are rated to:

- Microglass with pleated media: 99.98% removal of liquid and solid particles 0.3 micron.

- Microglass depth with graded density media: 99.9% removal of liquid and solid particles 0.3 micron and larger.

- Polypropylene with pleated media: 99.9% removal of liquid and solid particles 0.3 micron and larger for gas applications with trace amounts of amine.

Benefits:

- Increased personnel safety with easy cartridge removal with the extractor tool from the top area of the open coalescer vessel.

- Maximum protection for processes, equipment, and catalysts.

- Recovers carried-over liquids such as lube oil, amine, and glycol.

- Improves operational performance.

- Strong support cores can withstand differential pressure to 75 psi.

Operation Specifications for these Coalescing Cartridges:

- Flow direction is inside to outside.

- 0.3 micron rating.

- Recommended differential pressure for cartridge change-out is 15 PSI.

Features:

- Perforated support cores inside and outside help prevent collapse in upset conditions.

- Polyester outer wrap surrounds the pleated media to assist in drainage of the coalesced liquids.

- End caps, cores, and support materials are available in tinned steel, galvanized steel, 304 or 316 stainless steel, and synthetic materials.

- Buna gasket on the open end is standard. Also available in Viton, silicone, EPDM, or PTFE. Use Viton for amine applications where an abundance of hydrocarbons are present, otherwise EPDM may be used.

Standard Dimensions:

- 36” Long -- 5 ½” O.D. (other sizes can be furnished).

Standard Part Numbers and Beta Ratings:

WPML536Rb5-ET (99.98%) with microglass high-efficiency pleated media:

- Maximum operating temperature…. 275⁰ F.

- Minimum operating temperature……..35⁰ F.

WMGL536Rb1-ET (99.9%) with microglass high-efficiency depth media:

- Maximum operating temperature…. 275⁰ F.

- Minimum operating temperature……..35⁰ F.

WPPL536Rb1-ET (99.9%) with polypropylene high-efficiency pleated media for gas applications with trace amounts of amine:

- Maximum operating temperature…. 180⁰ F.

- Minimum operating temperature……..35⁰ F.