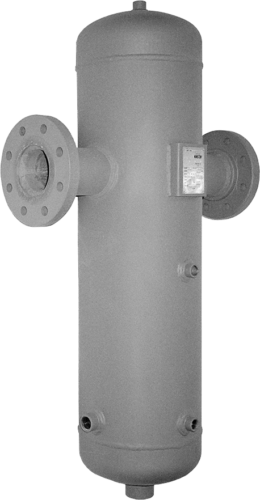

Vane separators for in-line installation

The Type 110V Vertical In-line Vane Separator is a 2-phase separator designed to remove mist and entrained liquids from gas, steam, or air. The design of the vane separator provides a high efficiency over a wide range of flow. Removal of 99.9% of 8-10 micron and larger liquid particles and small entrained solids can be expected for clean, dry gas or moisture-free steam. The compact separator is ideal for placement in limited spaces in refineries, gas plants, and petrochemical facilities, and the in-line nozzle orientation allows for easy installation. Where paraffins or sticky solids are expected and occasional cleaning is required, a flanged top with removable vanes can be provided.

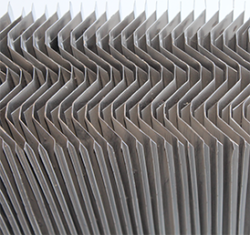

Principle of operation: Mist and entrained liquids are separated from the gas due to changes in flow direction as the gas passes through the tortuous path of the corrugated vane plates. Gas flowing through the vane is able to follow the changes in direction, however, inertial impaction causes liquid particles to separate as they are heavier and cannot easily change direction with the gas. Impinging on the vane surfaces, liquid particles coalesce as they travel along these surfaces and collect in the vane’s hooks. The hooks are installed vertically and are strategically placed at turns in the vane so as to intercept the liquid. The collected liquid moves down these hooks and into the bottom of the separator to drain out. Clean, dry gas exits the separator’s outlet.

- Removes 99.9% of liquid particles 8-10 micron size and larger.

- High turndown ratio - effective operation over a wide range of flow.

- Vertical design offers a small footprint for limited space applications.

- Removes small solid contaminants suspended in the liquids.

- Stainless Steel vane construction for a long operating life.

- ASME code stamped and National Board Registered.

Along with specific customer requirements some of the many options available are:

- Custom nozzle orientation

- Clean out ports

- Steel base mounting

- Lifting eyes

- Valve and control packages