Steam Sample Coolers • Boiler Water Sample Coolers • Process Liquid Sample Coolers

Winston/Royal Guard Series 500 Sample Coolers provide excellent heat transfer for cooling samples of hot water, process liquid, gas, steam, or vapor. The coolant can be cold water or other cool medium. The sample cooler can also be used to warm a cold sample using hot water, steam, or other hot fluid. For additional heat exchange, two or more sample coolers can be installed in series.

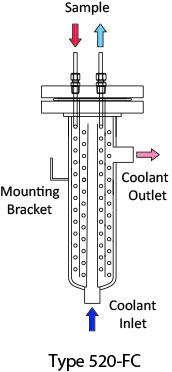

Type 520-FC Sample Coolers

Sample coolers are used to cool fluids or vapors to a point they can be safely handled for collection and analysis. With information found on the Sample Cooler Inquiry Questionnaire, a sample cooler can be provided for applications such as steam, boiler water, chemical processes, and others, in high pressure and high temperature ranges. For instance, steam sample coolers can provide condensate at a safe handling temperature. Boiler water sample coolers are critical for analyzing and treating boiler water to prevent scale buildup and corrosion.

The standard tubing design pressure for the sample side is 2000 PSIG. The standard external shell design is 285 PSIG (except for the Type 530 cooler). Higher pressure designs are available.

Tubing: The standard tubing material is 316 stainless steel and is available in 304 or 317 stainless steel, Monel®400, Nickel 200, Hastelloy®B and C276, Inconel®, and Incoloy®.

Shell: The standard material for the shell is carbon steel and available in any of the stainless steels and alloys shown above.

- The Type 520 provides the maximum heat transfer, featuring a much greater sample tubing length. The sample tube, in a double helix configuration, enters through the top of the cooler and coils down and around the interior of the shell before coiling up inside an interior chamber and out the top. The cooling medium enters at the top of the interior chamber and exits at the top side of the cooler exterior shell, providing a counter-flow of the sample and cooling mediums.

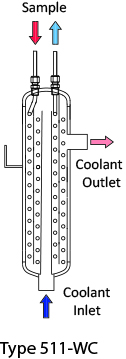

- The Type 511, similar to the Type 520 also has the double helix coil. The Type 511 features a fully welded top and bottom cap to enable higher shell pressure design and is not limited by flange pressure ratings.

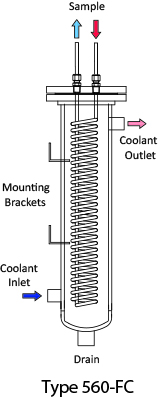

- The Type 560 features a flanged top for easy cleaning and a single spiral coil design. The sample medium in the tubing and the coolant in the shell side flow in a counter-flow, or opposite direction for maximum heat transfer.

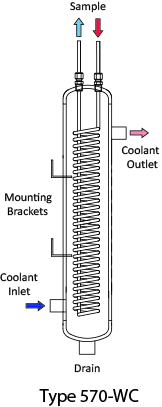

- The Type 570, similar to the Type 560 also has the single spiral coil. The Type 570 has a seal welded top for a more cost efficient design.

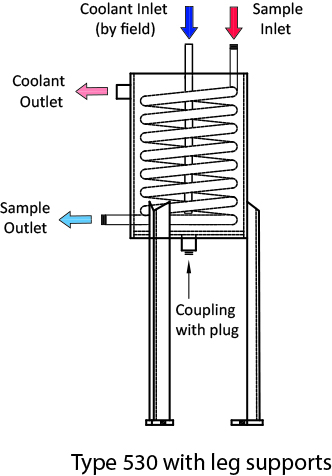

- The Type 530 features an open top design for use with low pressure cooling water.

Options include ASME Code stamp for the Types 520, 511, 560, and 570, support legs or mounting bracket, and other customer requirements.

ASME Code Certified: Winston/Royal Guard is an ASME Section Vlll, Division 1 Code certified manufacturing facility with National Board certification. Capabilities include all types of non-destructive testing with a rigidly controlled Quality Control system.