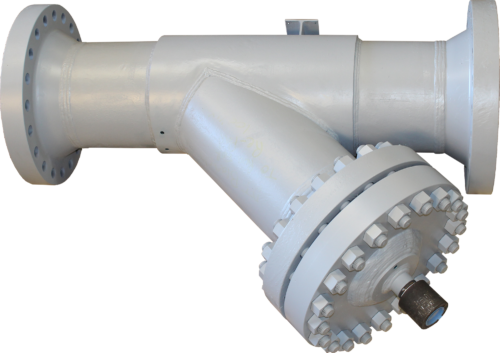

Fabricated Y Strainers remove sand, dirt, pipe scale, grit, welding beads and other unwanted solids from industrial liquids, gases, water, and steam

Type 57 Y, or WYE strainers are usually smaller and lighter in weight than other types of fabricated inline strainers. Y strainers are installed to protect pumps, compressors, valves, and downstream equipment by removing sand, dirt, pipe scale, grit, welding beads and other solids from liquids and gasses. When required, these strainers can be manufactured with longer face-to-face dimensions to match customer piping.

Applications include process gas, chemicals, hydrocarbons, process liquids, process water, steam, and others for the refining, chemical, petrochemical, pulp and paper, and other industries.

Standard material for the Y strainer body and flanges is carbon steel with 304 stainless steel basket (carbon steel, 316 stainless steel, and other alloys are optional). Some available materials are 300 series stainless steels (all or wetted parts only), Monel®400, Nickel 200, Hastelloy®B and C276, Inconel®, Incoloy®, and chrome moly. Except for chrome moly, the basket can be manufactured in any of these materials.

Internal perforated baskets are manufactured from heavy gauge materials and seam welded for maximum strength.

A complete selection of perforated metal and wire cloth is available for various openings and retention requirements. Typical basket openings are 80 mesh (0.0070”opening) for gas service, 40 mesh (0.0150” opening) for steam, and perforated with 1/8” diameter holes on 3/16” centers for process liquids. Most wire mesh sizes will have perforated support.

The basket access cover is available as a bolted blind flange with lifting handle or davit, or a quick-opening closure for easier and faster access for basket cleaning.

Y Strainer options include lifting eye(s), differential pressure connections, vent, blowdown coupling, and other customer requirements. Inlet/outlet styles include flanged or butt weld.

Manufacturing codes for Y strainers include ASME Section VIII, Division 1, ASME B31.3, B31.4, B31.8, B31.12, or in accordance with customer specifications.