Gas-Liquid Coalescers remove lube oil, mist and fine solid particles from a gas stream

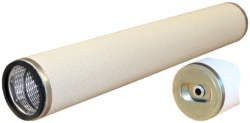

The Winston/Royal Guard Type 140 Gas-Liquid Coalescer is the solution for recovering aerosol, mist, and larger size liquid particles from a gas stream. Although primarily designed for liquid removal, extremely fine solids will also be captured. These gas coalescers have applications in natural gas processing, refining, petrochemical, and others. Gas-liquid coalescers are sometimes referred to as reverse flow coalescers, liquid-gas coalescers, or gas coalescers.

- Removes 99.9% of 0.3 micron particle size and larger. Maximum efficiency cartridges of up to 99.98% can be furnished.

- Removes liquid and solid contaminants from natural gas to protect compressors, turbines, glycol dehydrators and amine units, ammonia processes, molecular sieves and other catalyst beds, and other equipment.

- Improves operational processes and reduces maintenance costs.

How the gas-liquid coalescer works:

Liquid-entrained gas first enters the lower chamber of the coalescer vessel where the heavier liquid particles fall out due to the sudden change in velocity. The gas then flows into the coalescing cartridges. The direction of flow is from inside the coalescing cartridge through the media to the outside. This is the opposite flow direction as that of a standard filter cartridge, resulting in the often used term “reverse flow” coalescer.

As the gas flows through the cartridge media, aerosol and larger entrained liquid particles attach to the media fibers. As the flow continues, additional liquid particles attach to the fibers and merge, or coalesce, with other droplets. The heavier enlarged droplets then begin a downward gravitational descent through the fibers of the cartridge. This process continues until the droplets have grown large enough to release from the media and exit the lower portion of the cartridge. The liquid collects in the bottom of the cartridge chamber and is drained out of the vessel. The clean dry gas exits near the top of the coalescer vessel.

Cartridge change-outs:

The cartridge ET top caps and lock risers make maintenance easier and safer. The lock risers secure the cartridges in place and allow for loosening at the top of the vessel. An extractor tool is used for cartridge removal without entering the vessel.

The Type 140 Gas-Liquid Coalescer is an excellent choice for contaminant removal for gas production, transmission, and processing industries.

- Removes liquid hydrocarbons and other contaminants from natural gas to protect amine contactors from foaming and fouling.

- Recovers amine carried over from contactors.

- Removes contaminants from natural gas for the prevention of foaming and corrosion in glycol dehydration systems.

- Protects low and ultra-low NOx burner tips from contaminant fouling and loss of efficiency.

- Protects catalyst beds and other purification processes in plants.

- Removes water and solid contaminants from gas to protect dry desiccant dehydration systems.

Coalescing cartridges typically available for the Type 140 Gas-Liquid Coalescer include:

- WCL536R (0.3)-ET glass fiber depth type media in combination with polypropylene coalescing media with a rating of 0.3 micron at 99.9% efficiency.

- W--L536Rb-ET Series:

- WPML536Rb5-ET pleated microglass media with a rating of 0.3 micron at 99.98% efficiency,

- WMGL536Rb1-ET depth type microglass media with a rating of 0.3 micron at 99.9% efficiency,

- WPPL536Rb1-ET pleated polypropylene media with a rating of 0.3 micron at 99.9% efficiency for gas applications with trace amounts of amine.