For Winston/Royal Guard Type 61 Vertical and Horizontal Liquid Filters

With stainless steel wire mesh construction the WLST pleated series filter cartridges are designed to perform in applications outside the range of other filter medias. These cartridges can be provided in the Winston/Royal Guard Type 61V vertical and Type 61H horizontal Liquid Filtration units for removal of solid contaminants in industrial filtration applications with harsh, corrosive and/or high temperature liquids. The pleated design offers the maximum surface area for higher flow rates and longer operation time. Because of the metal construction, these cartridges can be cleaned and returned to service, thus providing extended life over other media types.

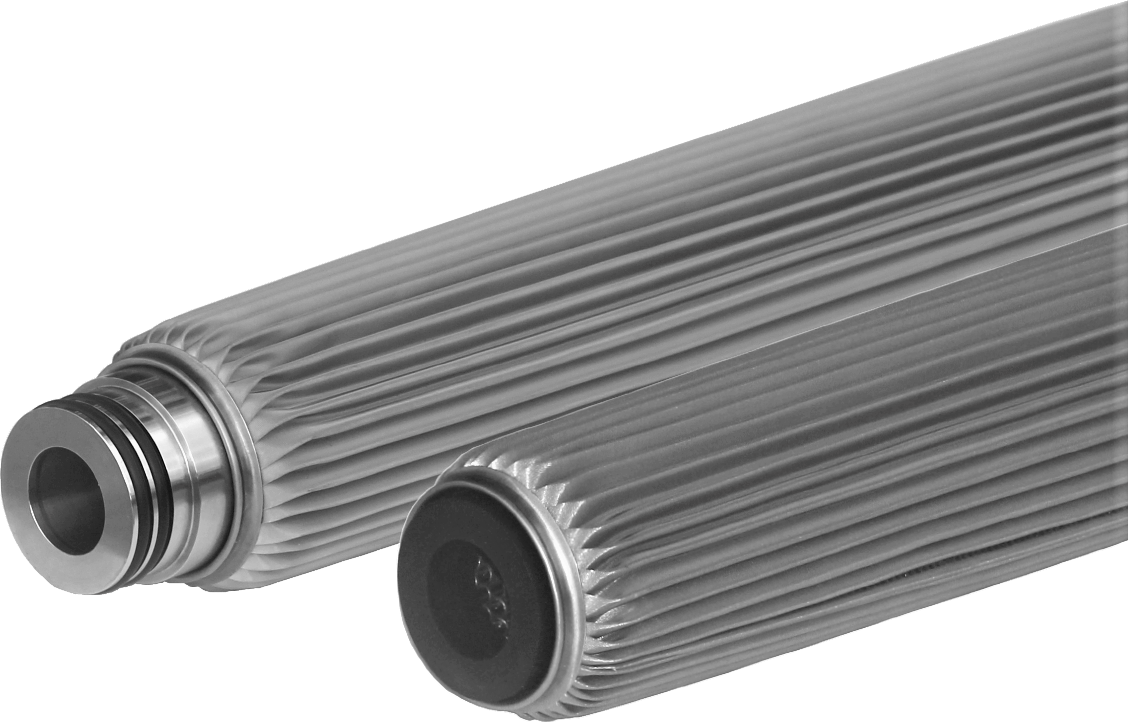

Shown above are two available bottom end treatments. Shown on the left is style 222 with O-rings. Shown on the right is a flat end, style FEG with gasket. Top end treatments are typically closed and with a spring assembly or a flat cap.

Benefits:

- Pleated design offers a greater surface area for lower differential pressure, higher flow rate, greater solids retention, and extended use between cleaning.

- Absolute efficiency ratings with known wire mesh opening sizes.

- Superior strength with woven and welded construction.

- Excellent for most corrosive and caustic services.

- Allows for higher temperature service.

- Savings in disposal costs with cleanable and reusable cartridges.

- Long service life.

Operational Specifications:

- FLOW DIRECTION is outside to inside.

- Absolute rated efficiencies from 5 to 840 microns.

- 60 PSI maximum differential pressure (300 PSI is available).

- Designed for operating temperatures from -100⁰ F to 500⁰ F (higher temperatures are available).

Materials:

- 304 or 316 stainless steel construction including mesh, core, and end caps.

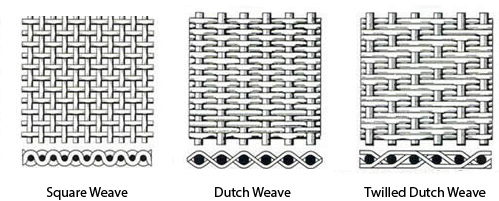

- Wire mesh: Square weave, dutch weave, or twilled dutch weave. Dutch weave and twilled dutch weave are methods of weaving the wires to provide stronger construction when required by the application.

- Large selection of O-ring and gasket materials (Buna, Viton, Teflon®, ethylene propylene).

Dimensions:

2-5/8” O.D., 1-1/8” I.D, with standard lengths of 10”, 20”, 30”, and 40”.

Typical Part Numbers:

- WLST316-20-SQ (5) 222T…. (316 SS, 20” long, square weave, 5 micron, 222 open end and Teflon® O-rings).

- WLST304-30-TDW (20) FEGB…. (304 SS, 30” long, twilled dutch weave, 20 micron, flat open end with Buna gasket).