For Winston/Royal Guard Type 61 Vertical and Horizontal Liquid Filters

For high flow industrial liquid process applications, the WHFP High Flow pleated series filter cartridge with inside to outside flow direction removes unwanted solid contaminants from liquid flows when provided in the Winston/Royal Guard Type 61V vertical or 61H horizontal liquid filtration units. The large diameter design offers higher liquid flow rates and maximum surface area for longer service life between cartridge change-outs. To meet industry filtration demands, a large selection of materials, lengths, particle size retentions, and efficiency ratings are available.

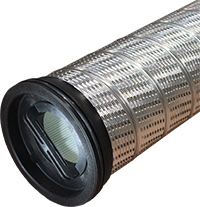

Shown above is a typical polypropylene filter cartridge with O-ring for a secure seal and lift-out handle for easy removal from the Type 61 filter housing.

Applications include removal of solid contaminants in liquid processes such as gasoline, diesel fuel, oils, amine, glycol, various chemicals, and many others in the natural gas, refining petrochemical, and chemical industries.

Benefits:

- Maximum solids retention with efficiency ratings up to 99.98%.

- Pleated media offers a greater surface area for longer operation between change-outs.

- Reduced maintenance costs and downtime.

- Improved operational performance.

Operational Specifications:

- Flow Direction is inside to outside.

- Wide selection of pleated materials and support layers.

- Large selection of O-ring and gasket materials (Buna, EPR, silicone, TEV, Viton).

- 6.3” nominal outside diameter with standard lengths of 40.5”, 60.5”, and 80.5”. Custom lengths are available.

- Recommended differential pressure for filter cartridge change-out is 35 PSI.

- Refer to individual filter cartridge part numbers for temperature limits.

Typical Part Numbers and Features:

WHFPP High Flow with pleated polypropylene media:

- End caps and external support: Thermally bonded polypropylene.

- Optional external support material: plated steel or stainless steel (304 or 316).

- Particle retention (micron size): 1, 2, 5, 10, 15, 20, 40, or 70.

- Efficiency ratings: 99.5%, 99.9%, or 99.98%.

- Maximum temperature: 180⁰ F.

- Typical part number: WHFPP64b10 (1) V…. (6.3” dia., 40.5” long, 99.9%, 1 micron, Viton O-ring).

WHFPE High Flow with pleated polyester media:

- End caps: Nylon with epoxy bond.

- External support: Plated steel. Optional 304 or 316 stainless steel.

- Particle retention (micron size): 1, 2, 5, 10, 15, 20, 40, or 70.

- Efficiency ratings: 99.5%, 99.9%, or 99.98%.

- Maximum temperature: 240⁰ F.

- Typical part number: WHFPE66b50 (20) T…. (6.3” dia., 60.5” long, 99.98%, 20 micron, TEV O-ring).

WHFPM High Flow with pleated microglass media:

- End caps: Nylon with epoxy bond.

- External support: Plated steel. Optional 304 or 316 stainless steel.

- Particle retention (micron size): 1, 2, 5, 10, 15, 20, 40, or 70.

- Efficiency ratings: 99.5%, 99.9%, or 99.98%.

- Maximum temperature: 275⁰ F.

- Typical part number: WHFPM68b02 (30) B…. (6.3” dia., 80.5” long, 99.5%, 30 micron, Buna O-ring).

WHFPCe High Flow with pleated cellulose media:

- End caps: Nylon with epoxy bond.

- External support: Plated steel. Optional 304 or 316 stainless steel.

- Particle retention (micron size): 1, 2, 5, 10, 15, 20, 40, or 70.

- Efficiency rating: 99%. Contact factory for higher efficiencies.

- Maximum temperature: 275⁰ F.

- Typical part number: WHFPCe66b01 (10) B…. (6.3” dia., 60.5” long, 99%, 10 micron, Buna O-ring).

WHFPCo High Flow with pleated cotton media:

- End caps: Nylon with epoxy bond.

- External support: Plated steel. Optional 304 or 316 stainless steel.

- Particle retention (micron size): 1, 2, 5, 10, 15, 20, 40, or 70.

- Efficiency rating: 99%. Contact factory for higher efficiencies.

- Maximum temperature: 300⁰ F with Viton O-ring. 250⁰ F with EPR O-ring.

- Typical part number: WHFPCo66b01 (10) E…. (6.3” dia., 60.5” long, 99%, 10 micron, EPR O-ring).