Providing industry the solutions for mist removal from gas and liquids from liquids, Winston/Royal Guard manufactures high performing coalescers in its ASME Code certified manufacturing facility.

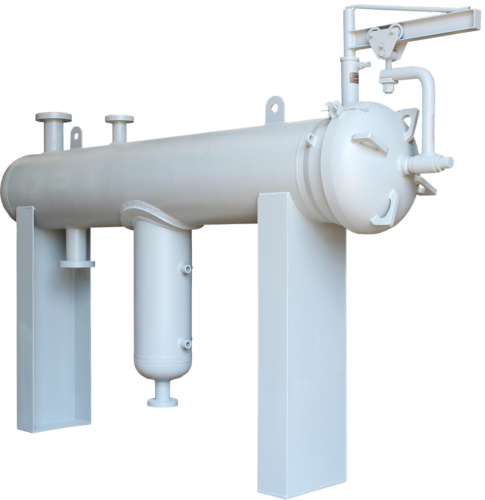

The Type 140 Gas-Liquid Coalescer recovers aerosol and larger size liquid particles from a gas stream. Although primarily designed for liquid removal, extremely fine solids will also be captured with the coalescing cartridges. Recovers lubrication oil downstream of compressors. Removes liquids from natural gas to protect compressors, turbines, glycol absorbers, desiccant dryers, molecular sieves, and other downstream equipment. Recovers carried-over foam in glycol and amine units.

The Type 62H-CC-2S Liquid-Liquid Coalescer Separator is a two stage coalescer utilizing both coalescing and separator cartridges for the separation of two immiscible liquids such as water from a hydrocarbon. Applications include separation of small amounts of water from oil, condensates, kerosene, gasoline, diesel, and others.

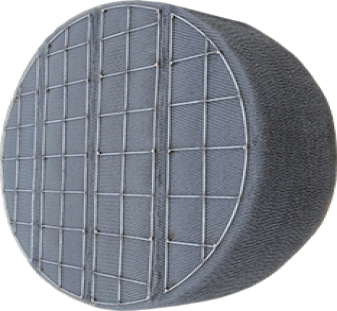

The Type 62HW-MM-1S Liquid-Liquid Coalescer is a single stage Liquid Liquid Coalescer used for the separation of two immiscible liquids, such as small amounts of water from a hydrocarbon (oil, gasoline, benzene, etc.). The unit utilizes a knitted wire mesh media pack for the coalescence and gravitational dropout of enlarged discontinuous phase droplets.

The Type 62HO-MM-1S Liquid-Liquid Coalescer, similar to the 62HW, is a single stage Liquid Liquid Coalescer used for the separation of small amounts of hydrocarbon from water. In this case, the boot is located on top of the vessel.